Polystyrene (PS, HIPS, GPPS, EPS)

Properties and Applications

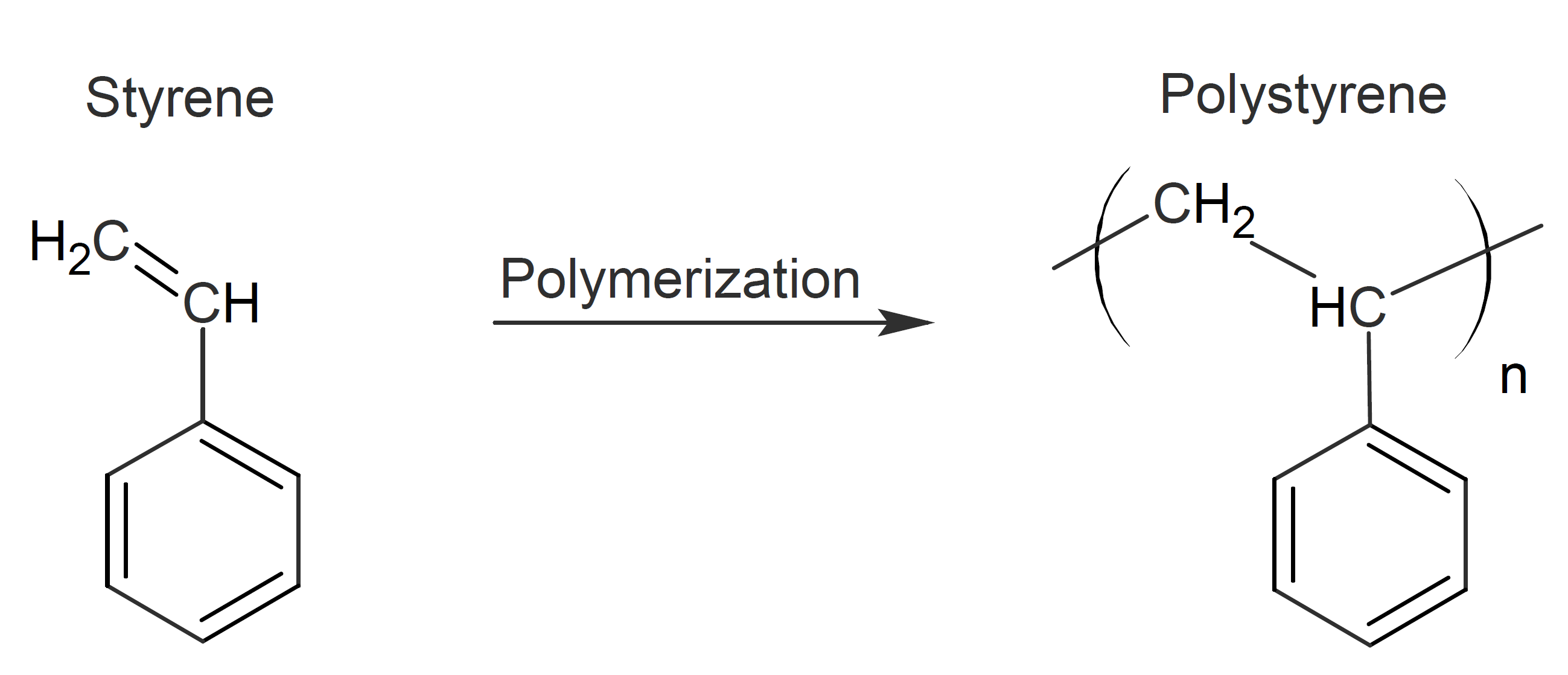

Polystyrene (PS) is is one of the largest volume commodity thermoplastics that can be converted into a large number of semi-finished products like foams, films, and sheets. This amorphous, nonpolar and low cost thermoplastic has excellent optical clarity due to the lack of crystallinity, good chemical resistance to diluted acids and bases, no odor and taste, and excellent thermal and electrical properties for insulation purposes.

It is also easy to fabricate into a large number of finished goods since the resin is a viscous liquid above its glass transition temperature that can be easily molded and foamed. However, polystyrene has several limitations; it is hard and rather brittle, has poor oxygen and UV resistance, is readily attacked by hydrocarbon solvents and its upper service temperature is relative low. Some of these limitations can be overcome by blending polystyrene with elastomers or by copolymerization with other monomers.

The three most important grades are:

GPPS: General purpose polystyrene, also known as crystal-clear polystyrene, is a fully transparent, rigid and rather brittle low cost thermoplastic made from styrene monomer. GPPS is a solid product manufactured in the form of 2-5 mm pellets.

HIPS: High impact polystyrene contains usually 5 to 10% rubber and is used for parts which require high(er) impact strength and flexibility.

EPS: Expandable polystyrene consists of micro-pellets or beads containing a blowing agent (usually pentane). The expanded or foamed polystyrene is thermally insulating, has high impact resistance and good processability.

PS is an inexpensive resin per unit weight and often a good choice for high volume, low cost applications. A large variety of products are manufactured by injection molding including dining utensils, food-packaging, plastic cups, housewares, toys, CD cases, cosmetic containers, covers and housings. It is also a popular material in the building and construction industry. Important applications include insulation foam, siding, panels, bath and shower units and various fixtures.

Manufacturers & Distributors

Companies |

Brands |